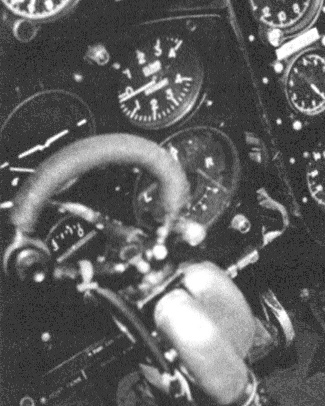

In order to build up a full set of instrument panels to represent DH.108 TG283, I have had to make many assumptions. For the blind flying panel – the set of 6 primary instruments – I have started with what I can see in the published photo of the cockpit (available in Rivas and Matthews1). See the snippet below. This looks like the typical fighters of the time, including the Vampire F.I, which the aircraft was built from.

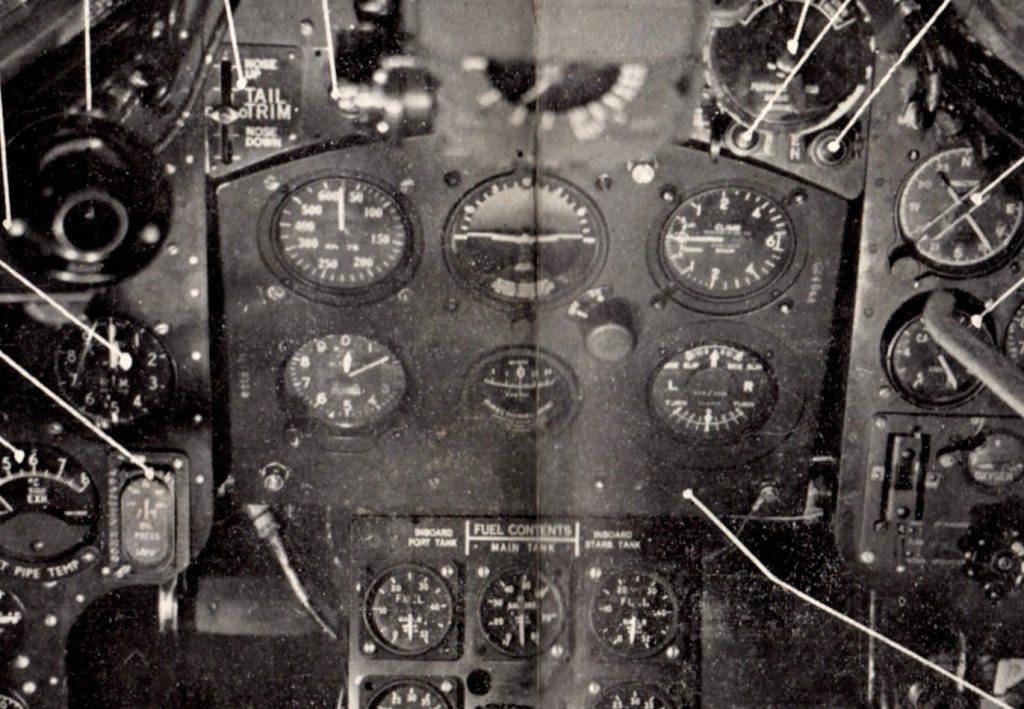

So I have assumed that the aircraft would have retained its original F.I BFP (below, from the AP.4099A Vampire F.I Pilot’s Notes); I have no reason to think that the air speed indicator or altimeter – the two on the left of the BFP – would be anything but standard. TG283 was the aircraft that was built for the low-speed range of the DH.108 flight test program; TG306 and VW120 (the other two DH.108 aircraft) at the high-speed end.

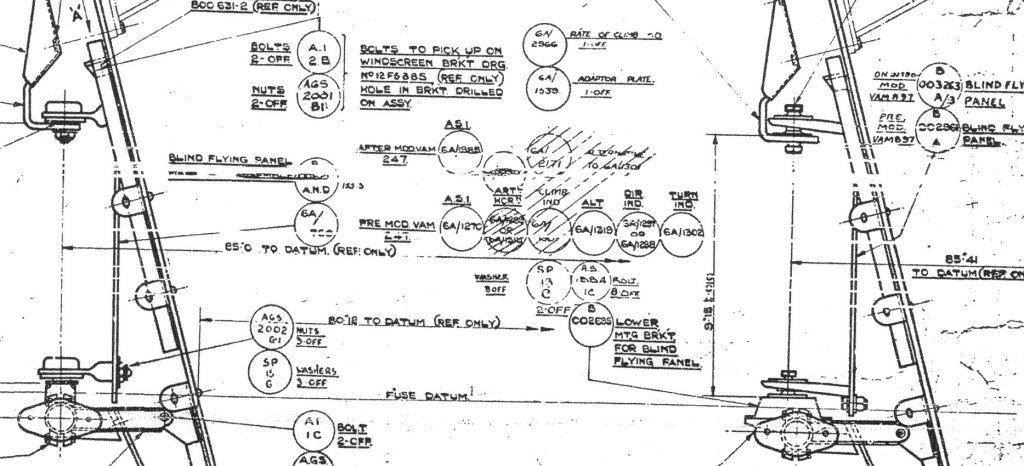

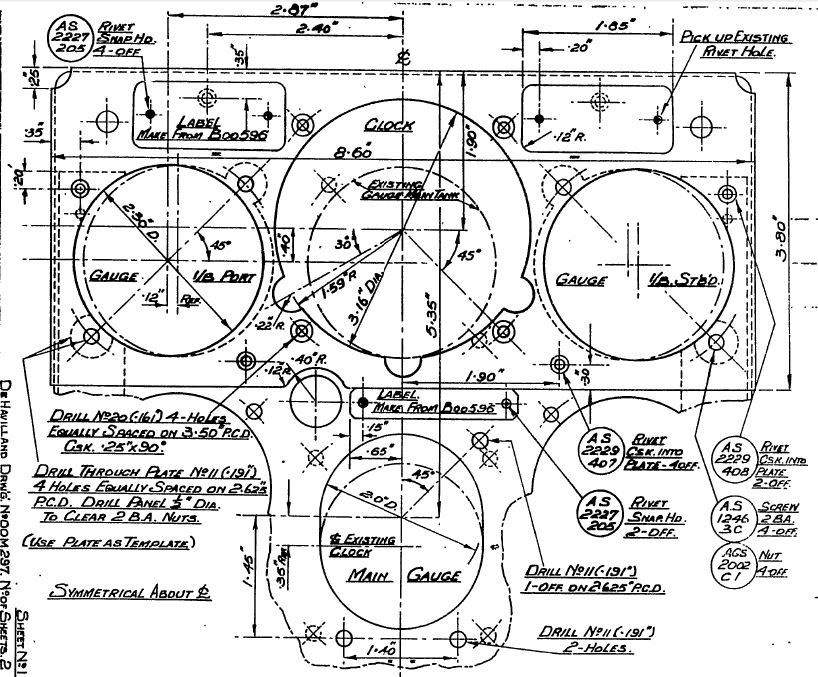

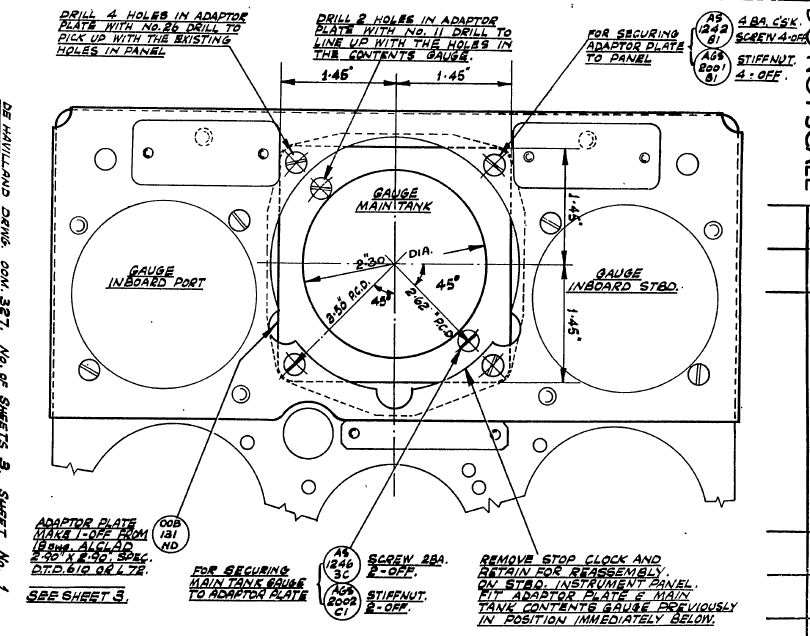

The instruments I have collected together are a reasonable match visually but ideally I would match the gauges fitted at the time. TG283 flew from May 1946 to May 1950. I don’t have the Vampire F.I schedule of spare parts or any drawings of the Mk.I, but I do have a drawing applicable to Vampire Marks 3, 4 (original Vampire Mk.II production designation), 5, 9 and 20 – snippet below. This shows some matches for what I have, but it’s only an indication.

The parts I have installed:

Air Speed Indicator Mk.9H* 6A/1985

Artificial Horizon 6A/1519

Rate of Climb Mk.IB* none

Altimeter Mk.XIVB 6A/1512

Direction Indicator Mk.IB 6A/1666, Sperry p/n 656557

Turn & Slip 6A/1302

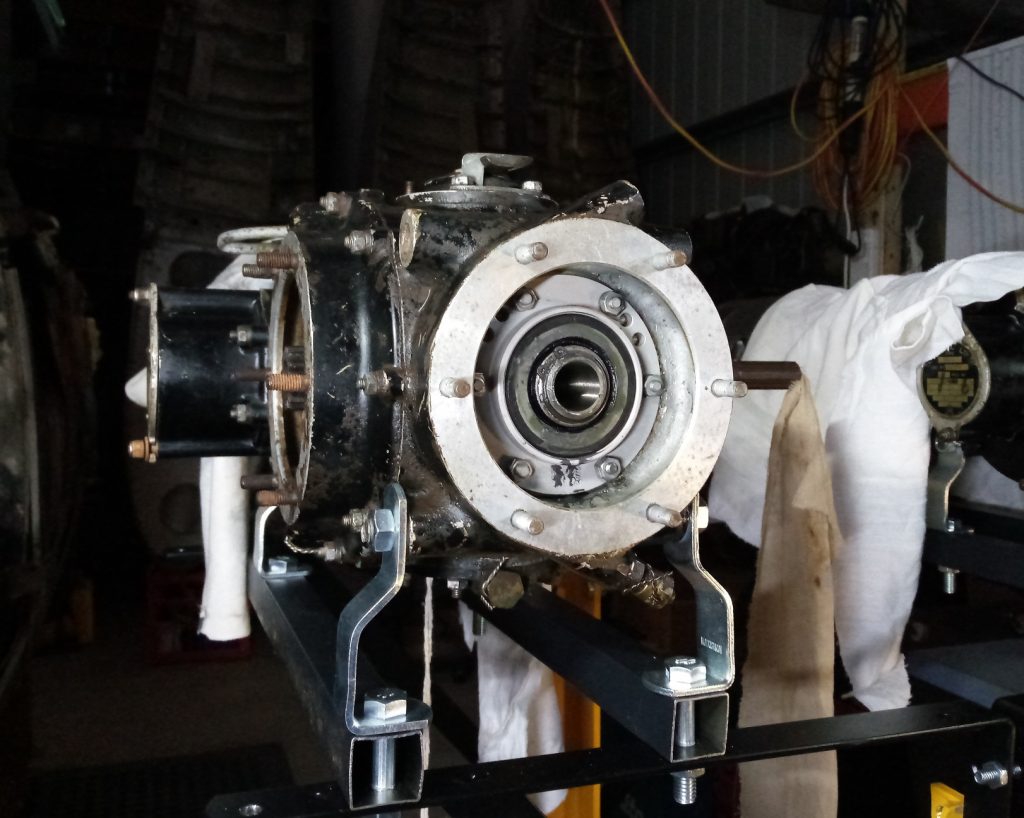

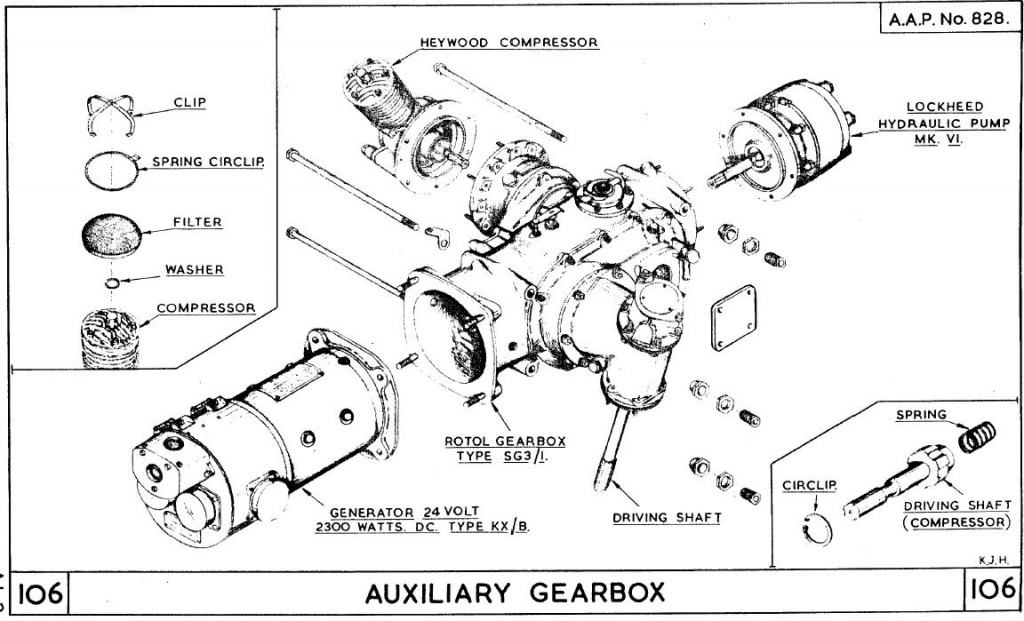

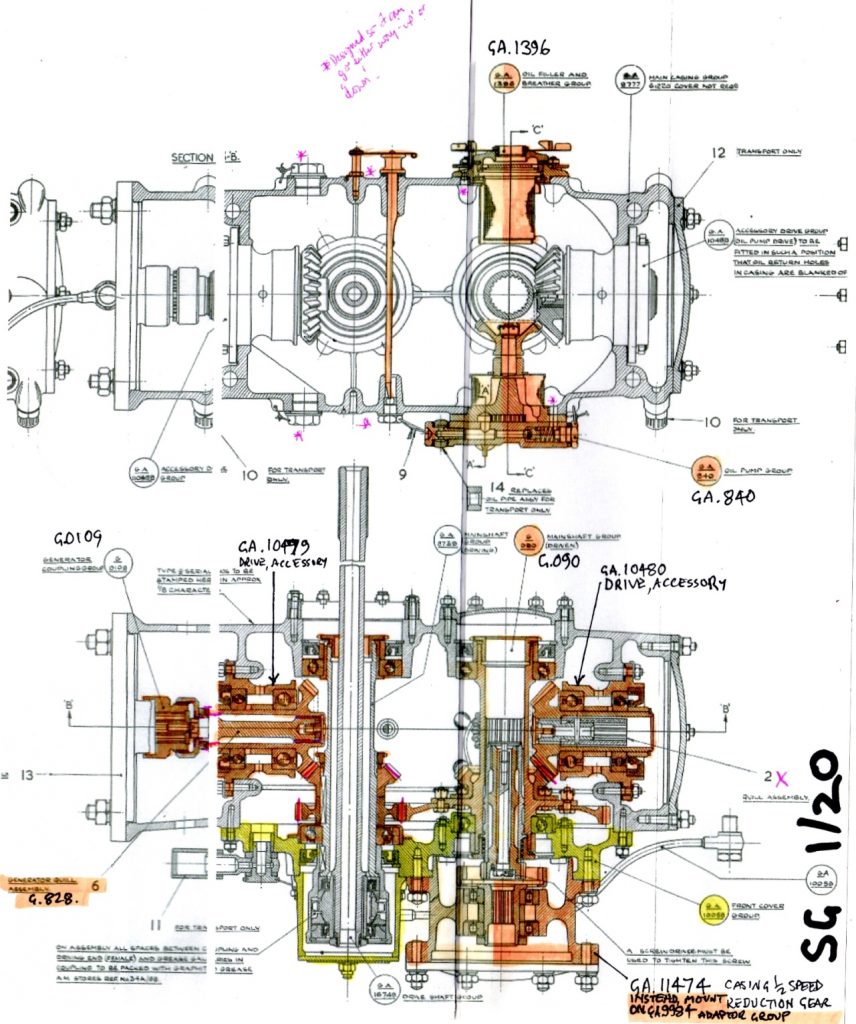

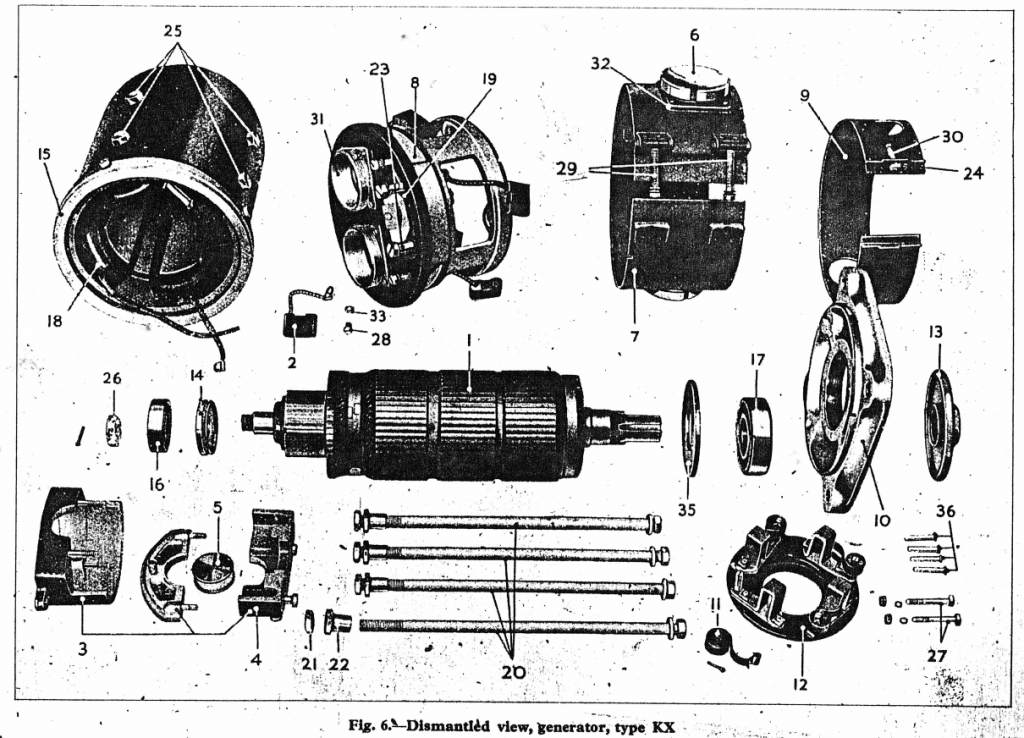

Like the early Vampire Mk.30 BFP I describe here, this panel reflects the World War Two era direct pitot-static systems for altimeter, ASI and rate-of-climb indicators, and vacuum-driven systems for the directional, artificial horizon and turn-and-slip gyro indicators. The vacuum or ‘suction’ for the latter three comes from a Pesco pump attached to the Goblin engine in the case of the DH.108 and Vampire F.I, and attached to the Rotol gearbox in the case of the Nene-engined Vampire Mk.30. The vacuum-driven systems were less effective at higher altitudes and were eventually replaced by electric gyro units. Vampire BFPs with electric gyro indicators are described here and here.

At this stage the whole panel assembly still needs a lot of work, with plumbing barely started – at the moment I just have the bare W.6216 suction box body – and leaving the mountings to a chance find for now.

1. Henry Matthews, DH. 108: The Saga of the First British Supersonic Aircraft, HPM Publications, Beirut, 1997

Thanks to David Collins for the instrument panel assembly drawing.